Cable description

GYFTC8S

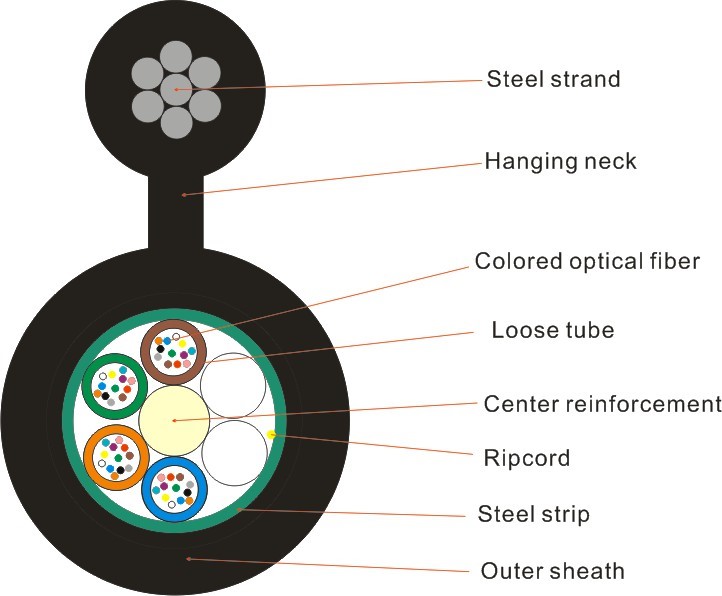

The outdoor optical cable adopts multi stranded plastic sheath (GYFTC8S) or plastic composite loose sleeve composite cable. The center of the cable core is a non-metallic reinforced core. For some cable cores, polyethylene (PE) layer is extruded from metal reinforced core. The loose tube (and filling rope) is wound around the central reinforcing core to form a compact round core, and the gap between the cores is filled with water blocking compound. After longitudinal binding of plastic coated steel strip, steel strand and polyethylene sheath of sling are added at the same time.

GYFTC8S Fiber

| No | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

GYFTC8S Tube

| No | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

GYFTC8S Structure parameter

| Item | Contents | Unit | Value | |

| Fiber count | Number | / | 24 | 48 |

| Cable structure | / | / | 1+6 | |

| Fibers per tube | Count | / | 4 | 12 |

| Central strength | Material | / | FRP | |

| member | Nominal Diameter | mm | 1.8 | 2.2 |

| Cable diameter | ±5% | mm | 9.2*17.5 | 10.4*18.7 |

| Outer sheath | Thickness | mm | Nominal 1.7 | |

| Cable weight | ±10% | kg/km | 196 | 218 |

GYFTC8S Mechanical & Environmental Performance

| Item | Contents | Value |

| Max. tensile load | Short term | 5000 N |

| Long term | 1600 N | |

| Max. crush resistance | Short term | 3000 N/100mm |

| Long term | 1000 N/100mm | |

| Min. bending radius | Installation | 20 x cable diameter |

| Operation | 10 x cable diameter | |

| Temperature range | Operation | -40℃ ~ +70℃ |

| Installation | -20℃ ~ +60℃ | |

| Storage/transportation | -40℃ ~ +70℃ |