Cable Introduction

GTTA53

Cable Description

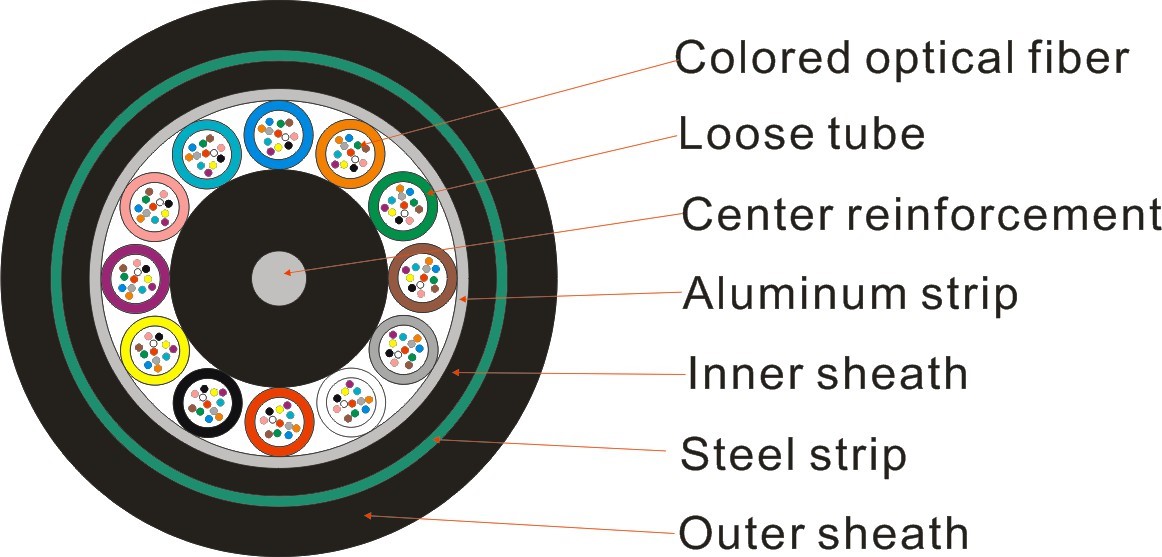

The structure of GYTA53 (metal reinforced member, loose sheath layer twisted filling type, aluminum polyethylene bonded sheath, longitudinal wrapped corrugated steel strip armor, polyethylene jacketed credit outdoor optical cable) optical cable is to sleeve single-mode or multi-mode optical fiber into the inner filled waterproof compound loose tube made of high modulus plastic. The center of the cable core is a metal reinforced core. For some cable cores, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and the filling rope) is twisted around the central reinforced core to form a compact and circular cable core, and the gap in the cable core is filled with water blocking compound. A layer of polyethylene inner sheath is extruded after the plastic coated aluminum strip is longitudinally wrapped, and the polyethylene sheath is extruded after the double-sided plastic coated steel strip is longitudinally wrapped.

GYTA53 Fiber

| No | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

GYTA53 Tube

| No | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

GYTA53 Structure parameter

| Item | Contents | Unit | Value | ||||

| Fiber count | Number | / | 24 | 48 | 72 | 96 | 144 |

| Cable structure | / | / | 1+6 | 1+5 | 1+6 | 1+8 | 1+12 |

| Fibers per tube | Count | / | 6 | 12 | |||

| Central strength | Material | / | Steel wire with PE cushion when necessary | ||||

| Nominal Diameter | mm | 1.8 | 1.8 | 2/2.8 | 2/4.4 | 2/7.9 | |

| Cable diameter | ±5% | mm | 12.5 | 13.9 | 14.9 | 16.6 | 20.2 |

| Outer sheath | Thickness | mm | 1.8 | ||||

| Cable weight | ±10% | kg/km | 165 | 198 | 227 | 272 | 381 |

GYTA53 Mechanical & Environmental Performance

| Item | Contents | Value |

| Max. tensile load | Short term | 3000 N |

| Long term | 1000 N | |

| Max. crush resistance | Short term | 3000 N/100mm |

| Long term | 1000 N/100mm | |

| Min. bending radius | Installation | 25 x cable diameter |

| Operation | 12.5 x cable diameter | |

| Temperature range | Operation | -40℃ ~ +70℃ |

| Installation | -30℃ ~ +60℃ | |

| Storage/transportation | -40℃ ~ +70℃ |